WirralCar Repairs

Calipers

- Caliper Housing

- Piston

- Seals & Dust Boots

- Brake Pad Clips

- Bleeder Screw

Common Issues

- Dashboard warning light

- Leaks

- Vehicle pulls to one side

- Uneven brake pad wear

- Reduced stopping power

- Soft spongey brake pedal

- Clunking sound

- Squealing

- Smells

What Is Disc Brake Caliper?

A brake caliper is a vital part of the vehicle's braking system. It is pivotal in decelerating the wheels and bringing the vehicle to a halt. A brake caliper is an important part of a vehicle's braking system. It converts hydraulic pressure into mechanical force to slow or stop the vehicle. Its functioning involves the precise movement of pistons, which press the brake pads against the rotor, generating friction and decelerating the wheels. Constructed with sturdy materials and various components, brake calipers come in different types, such as floating, fixed, and sliding calipers, each offering distinct advantages and catering to specific vehicle types and performance requirements. The design and engineering of brake calipers are vital to ensure safe and efficient braking performance.

Functioning of a Brake Caliper

The braking system in a vehicle is a complex arrangement of components whose sole objective is to slow down or bring the vehicle to a complete stop. The system has the brake pedal, master cylinder, brake lines, brake calipers, brake pads, and brake rotors (also known as brake discs).

The brake caliper is a housing for the brake pads and is responsible for transforming hydraulic pressure into mechanical force. When the driver pushes the brake pedal, the hydraulic pressure from the master cylinder is transmitted to the brake caliper. As the hydraulic pressure reaches the brake caliper, it enters the caliper housing and exerts a force on the pistons inside. The pistons, typically made of metal or composite materials, respond to the hydraulic pressure by moving outward from their original positions within the caliper housing.

The outward movement of the pistons forces the brake pads to come into contact with the brake rotor on both sides. The brake pads, also made of friction material, grip the rotor tightly when pressure is applied. This action generates friction between the brake pads and the rotor, slowing down or stopping the rotation of the wheels.

The clamping force exerted by the pistons on the brake pads determines the effectiveness of the braking action. The more force applied, the stronger the braking power. This force is modulated by the driver's input on the brake pedal, allowing for varying degrees of braking force depending on the situation.

Once the brake pedal is released, the hydraulic pressure in the brake lines is reduced. As a result, the pressure inside the caliper decreases, allowing the pistons to retract back into their original positions.

The retraction of the pistons creates a gap between the brake pads and the rotor, effectively releasing the clamping force. With the brake pads no longer in contact with the rotor, there is no friction, and the wheels can rotate freely again.

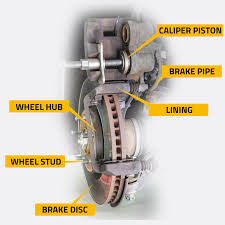

Operation of Disc Brake System (Disc Brake Working Principle)

By pressing the brake pedal, the pressurized hydraulic fluid from the brake master cylinder comes to the connection union on the caliper via the brake hydraulic hose. The hydraulic oil entering the caliper cylinder from the fitting pushes the piston in the cylinder forward, and by the forward movement of the piston, the pad is pressed right in front of the brake disc. With the friction of the pad against the disc, the wheel slows down and stops.

The disc brake system is also based on the Pascal principle. The mechanical force generated in the brake pedal is converted into hydraulic pressure in the brake master center, this hydraulic pressure is converted back into mechanical force in the caliper. The motion energy of the vehicle is converted into heat energy by the pads rubbing against the disc.

Construction of a Brake Caliper

- Caliper Housing: The caliper's main body houses the other components and encloses the brake pads and rotor.

- Pistons: These are cylindrical components located inside the caliper housing. When hydraulic pressure is applied, the pistons extend outward to push the brake pads against the rotor.

- Seals and Dust Boots: These ensure a tight and reliable seal around the pistons, protecting them from dirt and contaminants. Proper seals are vital to prevent brake fluid leaks and maintain hydraulic pressure.

- Brake Pad Clips: These clips securely hold the brake pads within the caliper.

- Brake gap (pad-disc) can be adjusted by itself

- Bleeder Screw: A small screw used to release air and excess brake fluid from the caliper during brake bleeding procedures.

In addition to these components, modern brake calipers often include advanced features, such as anti-rattle clips and electronic brake pad wear sensors, to enhance performance and safety

Different Types of Brake Calipers

Floating Calipers: Floating calipers are the most common type used in modern vehicles. They have one or two pistons on one side of the rotor. When the brakes are applied, the caliper slides inward, causing the piston(s) to press the brake pads against the rotor. Floating calipers are relatively simple and cost-effective, widely used in various vehicles.

Fixed Calipers: Fixed calipers have pistons on both sides of the rotor, providing more even pressure distribution and improved braking performance. Unlike floating calipers, fixed calipers do not slide; they remain stationary during braking. This design reduces caliper flexing and ensures a more consistent brake pad-to-rotor contact.

Sliding Calipers: Sliding calipers are also known as pin-slide calipers. They have one or two pistons on one side of the rotor, similar to floating calipers. However, sliding calipers use pins or sliders to allow the caliper to move back and forth slightly during braking. This design helps equalize pressure on both sides of the rotor and promotes even brake pad wear.